In the Classification app every assortment contains a matrix of segments. Each of these segments contain groups of parts, defined by the 2 dimensions of the matrix. For example: cheap fast movers (A1 in default configuration) or expensive slow movers (C3 in default configuration).

For each segment you can assign settings. The default settings are based on the planning concepts that are associated to the different segments.

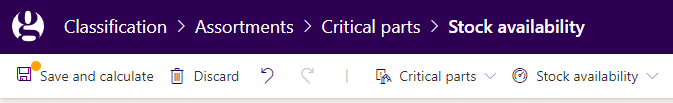

There are different setting groups that can be set, see below. All settings that are set for a segment are applied on part-level after pressing Save and calculate.

The setting groups are:

In addition, you can change the planning concept that is associated to that segment by clicking on that segment and then change the planning concept.

Note that only admin users can configure a planning concept. You can contact Lanza support.

The stock availability target defines the risk of a stock-out and has a direct impact on the safety stock calculation. The higher this number the higher the safety stock. Typically you set higher targets for cheap fast movers than for expensive slow movers. Contact Lanza support for more in-depth coaching on availability settings.

Demand forecast settings contain a hierarchy of settings.

Now the complete list of forecast settings appears. The most important setting is the planning method. There are 4 options:

The order quantity method determines in which way the order quantity is determined. An order quantity method can be set as long as the active inventory model for a segment is not ‘Slow‘. Typically this inventory model is associated to segments C2 and C3. For this inventory model the order quantity defaults to 1, as we are using a base stock policy.

The following order quantity methods can be applied:

The lead time method dictates how the lead time is determined. For each segment, a lead time method is chosen for both purchase lead time, and if applicable, repair lead time. The following methods are available:

The export settings determine which segments are in scope for the parameter update. When this setting is set to ‘No’ the inventory parameters of that segment will be not be included in the export list towards the ERP system. Contact Lanza support for more information on the configuration of your inventory parameter export.

Kerkweg 10,

3603 CM Maarssen

Vineyard Office Estate,

99 Jip De Jager Drive,

De Bron, 7530

©Copyright 2024 | All Rights Reserved | Lanza Solutions