The basis for each planning concept is an inventory model. Lanza has three inventory models: Fast, Slow, Non.

For fast movers, Lanza uses an (R,s,Q)-inventory model, calculating the reorder point (s) and order quantity (Q). Inventory is reviewed every (review) period (R). When the inventory drops below the reorder point, a replenishment is triggered to replenish the inventory with the order quantity (Q).

This model

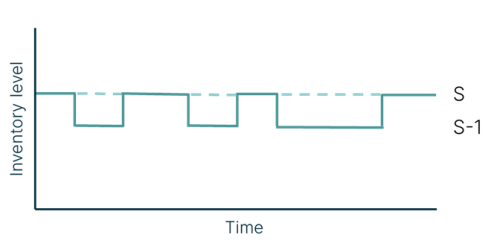

For slow movers, Lanza uses an (S-1,S)-model, calculating a base stock level. When inventory drops below the base stock level (S), a replenishment is triggered to replenish the inventory back to the base stock level.

This model

For non-movers, Lanza uses no inventory model, as there is no demand. Here the required stock level is by definition zero, e.g. for non-movers or obsolete parts.

This model

Kerkweg 10,

3603 CM Maarssen

Vineyard Office Estate,

99 Jip De Jager Drive,

De Bron, 7530

©Copyright 2024 | All Rights Reserved | Lanza Solutions