Inject the best lead time

Knowing your supplier lead time is crucial in determining your stock levels. At the same time this data is not maintained well in legacy systems. In Lanza you can pick your best source and simulate what the best outcome would be.

Use actual lead times when reliable

When a part is born, Procurement takes a best guess on the lead time. Or when you are lucky you can take it from the contract that is created with the supplier. Unfortunately, reality is always different.

Since Lanza is keeping track of all the purchase and repair orders you are able to choose the actual lead time based on these transactions. In fact, Lanza automatically falls back to the default lead time when these transactions are not reliable enough. For example, if you only have a few transactions or when the variability is simply too high. Lanza will always inject the best possible input for your stock calculation.

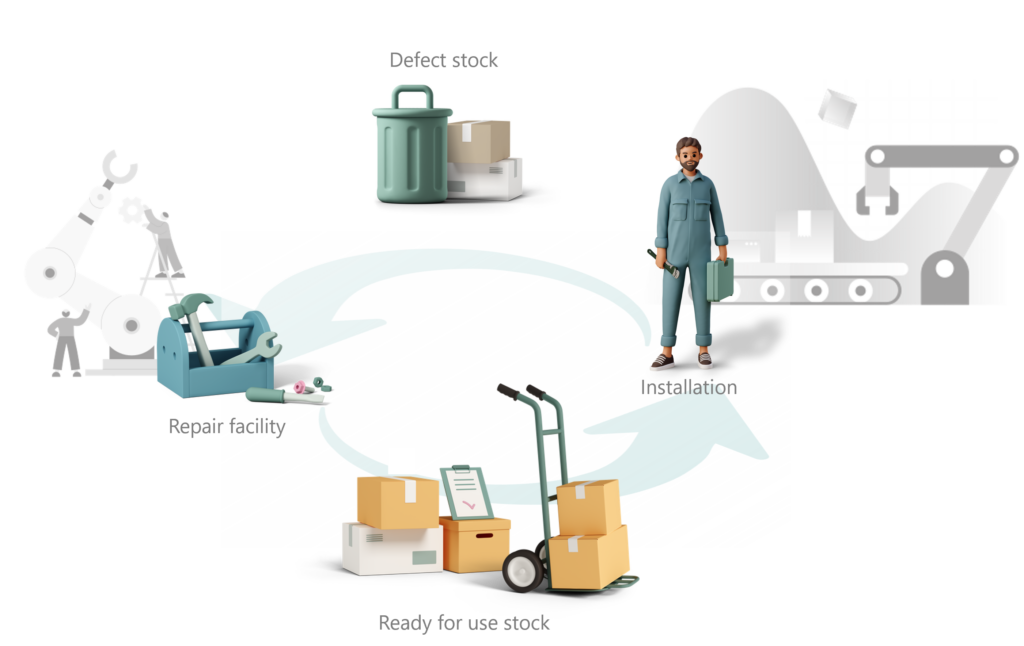

Manage your repairables

Apart from consumable or regular parts, Lanza manages your repairables as well. Apart from your new buy supplier lead time Lanza also takes into account the repair lead time. When the information is available Lanza uses the scrap rate to determine a weighted total lead time. In fact, the higher the scrap rate the more often you must buy a new spare, but the lower the scrap rate, the more often you can repair the item. This is all taken into consideration automatically.