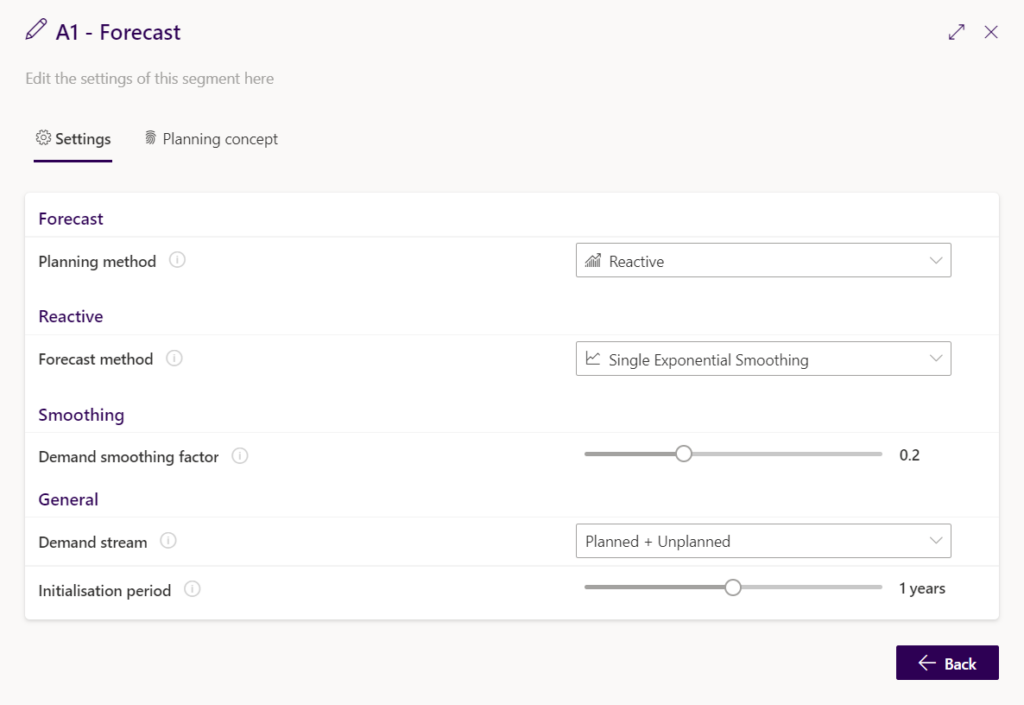

Lanza offers three planning methods: reactive, proactive, and mixed. For each planning method, different forecasting algorithms are available. These settings can be adjusted on a segment level and part level.

Configurable settings include:

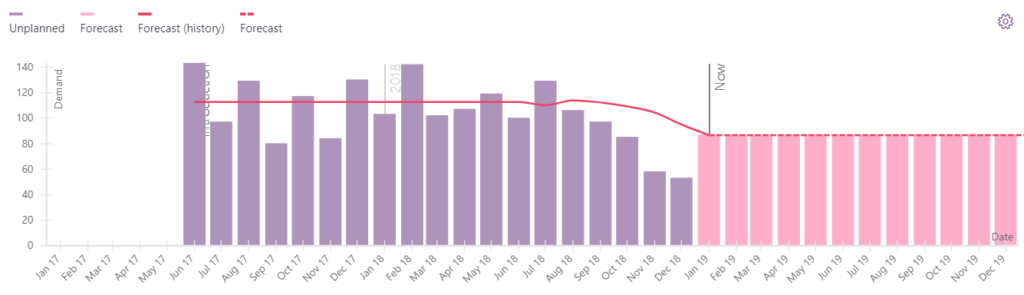

This planning method is suitable for forecasting based on historical demand. Lanza offers specialized forecasting algorithms aimed at fast moving and slow moving parts.

Lanza offers multiple forecasting algorithms for fast moving parts. Where applicable, smoothing factors can be adjusted.

Lanza offers specialized forecasting algorithms for slow moving parts. Because of the lack of data, regular forecasting methods often do not provide accurate results. For more information on forecasting slow movers, see Slow mover management.

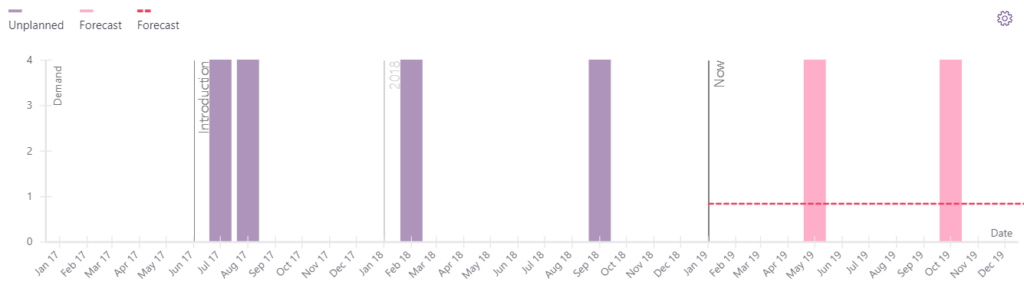

This planning method is suitable for forecasting based on future expected demand. Future expected demand is typically gathered from planned maintenance schedules, sales forecasts, production planning, or other sources of future demand.

Within future expected demand, Lanza differentiates between different demand streams, such as fixed reservations (amount and timing of demand is known beforehand, e.g. for preventive maintenance) and projected demand (amount and timing of demand is uncertain, e.g. for inspection based maintenance). It is possible for Lanza to assist in creating future expected demand based on reliability information. For more information, see reliability-based planning.

Using proactive planning, the reorder point is calculated based on the expected demand of a specific future planning period. This planning period can be configured by the user by adjusting the planning window. Using default settings, the planning window is the period between t0 + lead time ↔ t0 + lead time + lead time.

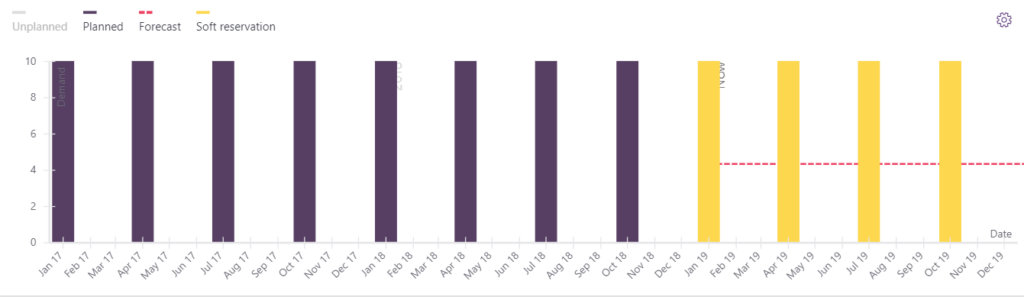

This planning method is suitable for forecasting based on a combination of historical and future expected demand.

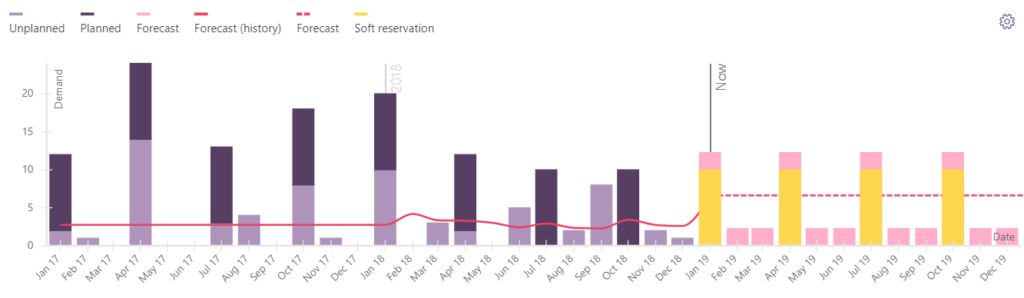

Within historical demand, Lanza differentiates between different demand streams, such as planned and unplanned demand. In an ideal world you apply a reactive forecast (based on historical demand) on your historical unplanned demand, and you combine this with future reservations for your planned demand. This requires the distinction between planned and unplanned demand in the available data.

A specialized forecasting method, developed for the MRO world, uses reliability information.

In this approach, Lanza forecasts demand based on:

This requires a proper set up of the Bill Of Material. If this is available the behaviour of an asset installed base can be used to guide the demand forecasts on part level.

Kerkweg 10,

3603 CM Maarssen

Vineyard Office Estate,

99 Jip De Jager Drive,

De Bron, 7530

©Copyright 2024 | All Rights Reserved | Lanza Solutions