Managing supply is essential in spare parts management. Lanza supports this process in several ways. Amongst others by using realistic lead times, giving insight into historical supply, and by optimizing your purchasing efficiency.

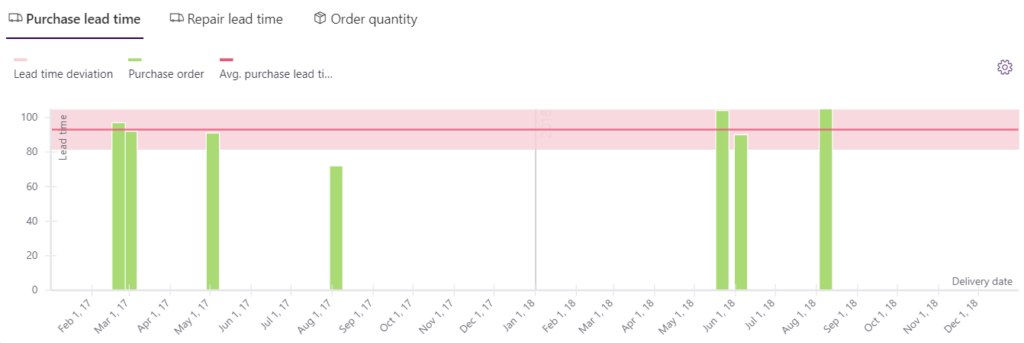

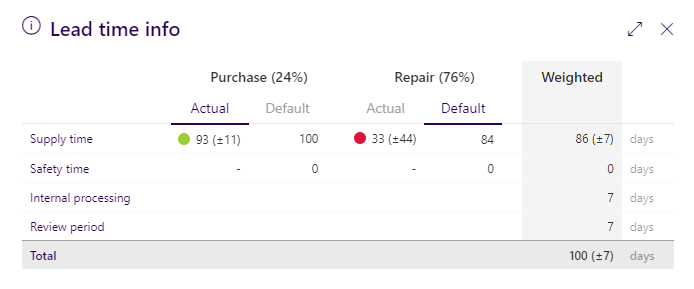

Realistic lead times are essential to accurately determine inventory levels. In Lanza, there are three ways to determine what lead time to use in calculations:

* when reliable: with the setting ‘Actual’, the historical lead times are only used when they are considered reliable. This depends on the lead time deviation compared to the average lead time, and the number of deliveries. These parameters can be set in the global settings. If the lead times for a certain part do not comply with these conditions, the default lead time is used.

On top of the lead time from the supplier, it is important to consider any internal processing time that is necessary to acquire new parts. In Lanza, these are split up into internal processing time (i.e. the time to promote a purchase requisition into a purchase order and the time to receive goods in the warehouse) and review period (i.e. the interval that is used to replenish, e.g. once a week)

These additional lead times can be configured per segment and on a part level.

For repairable parts, Lanza also accounts for the difference between new-buy purchase and repair lead times. For more information, see Repairables.

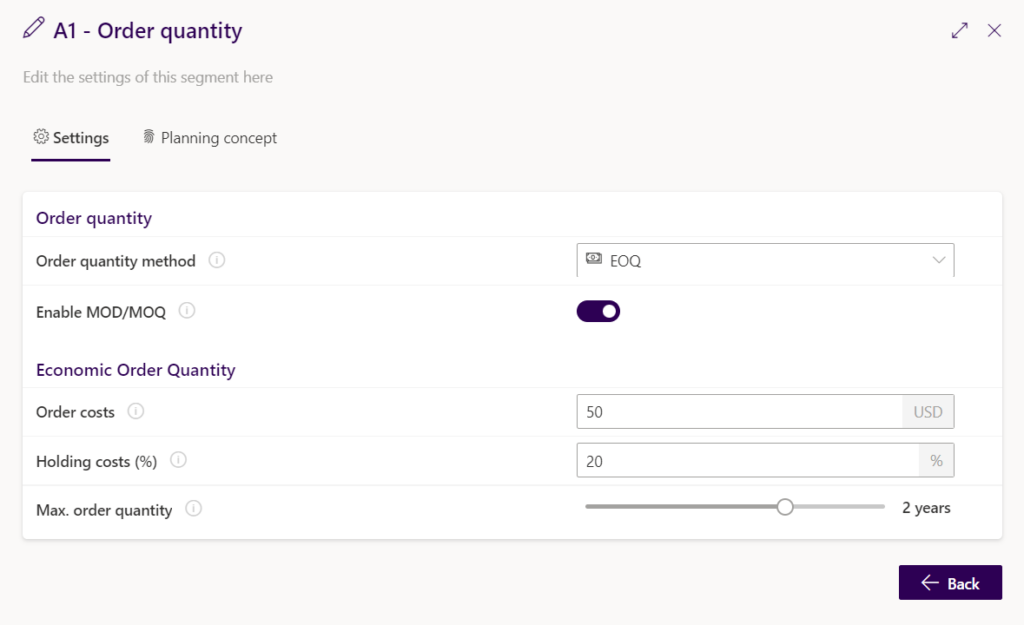

Correct order quantities are important to optimize your purchasing efficiency. For this purpose, Lanza calculates optimal order quantities. This is done with three methods:

Lanza is able to account for supply restrictions imposed by suppliers or other factors. If the data is available, a planner can choose to account for or ignore the MOQ/MOD restrictions. This can be done on segment level or part level.

A minimum order quantity (MOQ) dictates that the order quantity should be at least the value of the MOQ. If activated, Lanza compares the calculated order quantity with the MOQ. When the calculated order quantity is lower, the MOQ is used as order quantity. Otherwise, the calculated order quantity is used. The MOQ is often used to account for supplier restrictions.

A rounding order quantity (MOD) dictates that the order quantity should be a multiple of the MOD value. If activated, Lanza rounds the calculated order quantity to the closest, or optimal, multiple of the MOD. The MOD is often used to account for packaging sizes. For example, there are 100 screws in a container and purchasing is done per container. When the calculated order quantity gives an outcome of 107 pieces, the MOD makes it 100 pieces.

Kerkweg 10,

3603 CM Maarssen

Vineyard Office Estate,

99 Jip De Jager Drive,

De Bron, 7530

©Copyright 2024 | All Rights Reserved | Lanza Solutions