When your inventory network consists of multiple inventory points, the entire network can be optimized using multi-echelon optimization (MEO). As the inventory level at an inventory point influences the expected availability of other inventory points, an integral optimization is required.

In inventory networks, echelons are different distribution levels, representing a link in the supply chain network. Inventory points in a certain echelon typically receive supply from an upstream echelon and fulfill demand for a downstream echelon.

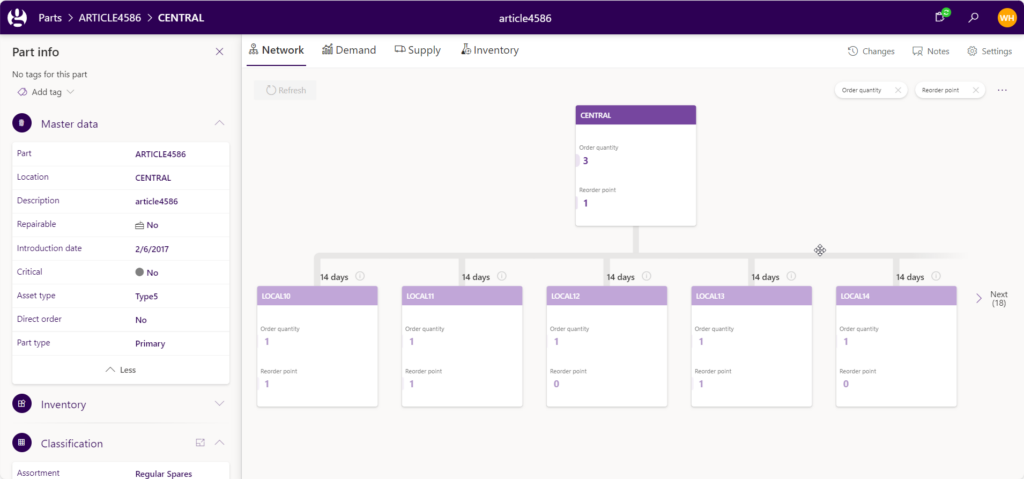

In Lanza, this is modelled by differentiating between local and central warehouses. Local warehouses are network end-points that directly serve customer orders, while central warehouses are all intra-network warehouses that serve network replenishment orders.

The algorithm used for MEO is based on consists of four steps:

The calculations are based on a ‘waiting time’ principle, where the lead time for local warehouses is based on the (expected) waiting time for the central warehouse.

In some, more complex networks, an inventory point can serve as a supplier for downstream echelons but also serve direct customer demand. In this case, Lanza combines direct and downstream demand for this inventory point, making sure that customer availability targets are achieved and total inventory value is optimized.

Kerkweg 10,

3603 CM Maarssen

Vineyard Office Estate,

99 Jip De Jager Drive,

De Bron, 7530

©Copyright 2024 | All Rights Reserved | Lanza Solutions